1963 Ford 4000 Manual Steering Gear Box Exploded View

< PREV Page NEXT Page >

A1

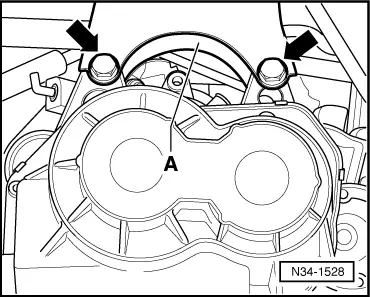

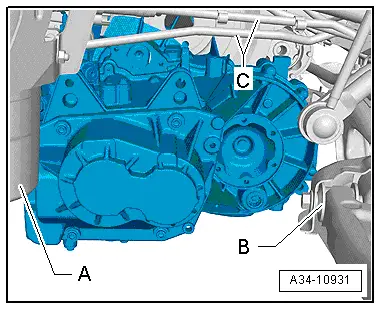

Removing gearbox

Special tools and workshop equipment required

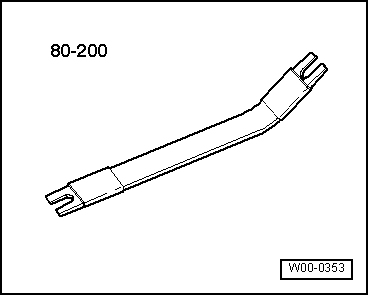

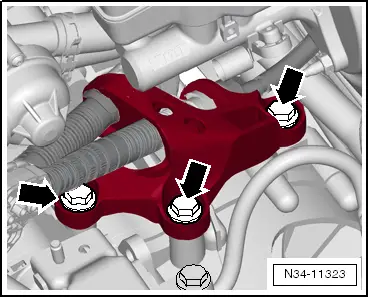

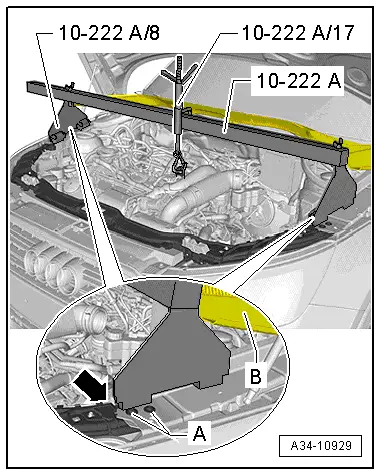

| t | Support bracket -10 - 222 A- |

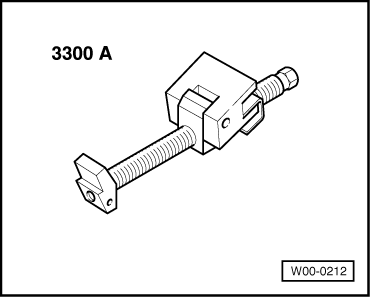

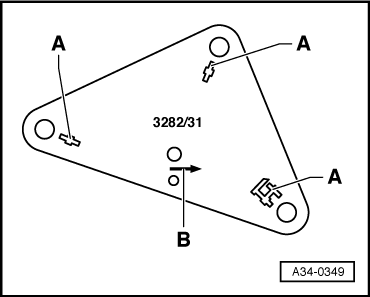

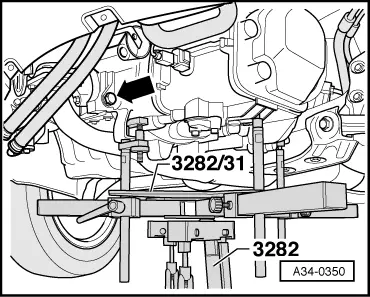

| t | Gearbox support -3282- |

| t | Adjustment plate -3282/31- |

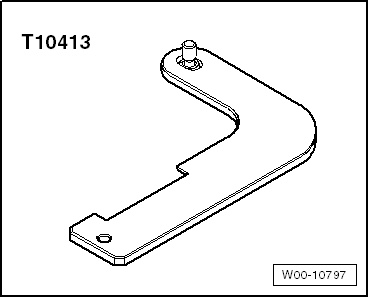

| t | Engine and gearbox jack -V.A.Thousand 1383 A- |

|  |

|  |

|  |

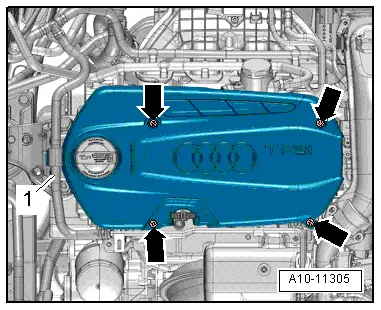

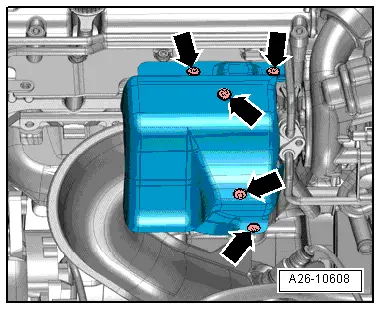

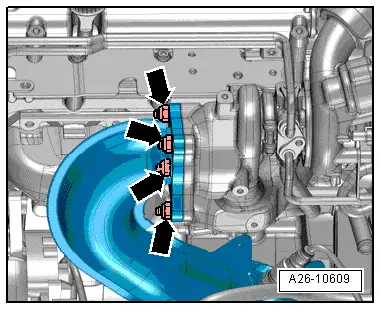

| Procedure Re-adhere all cablevision ties at the aforementioned locations when re-installing.

|  |

-Detail 2- tin can be overlooked. |  |

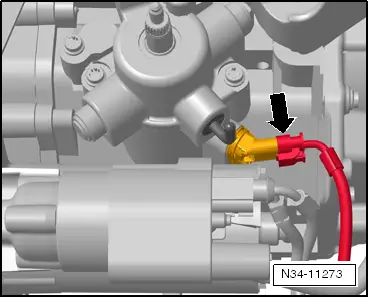

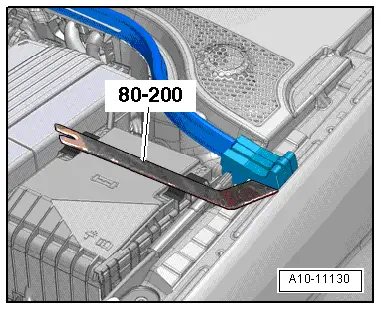

When disconnecting the battery at that place is a gamble of serious damage to electronic components: Observe the correct procedure for disconnecting the bombardment. |  |

|  |

|  |

|  |

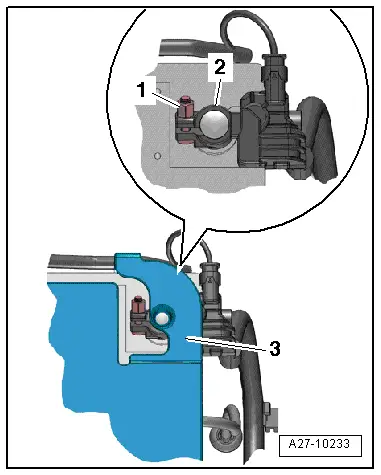

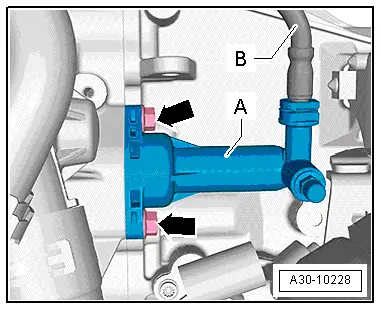

Run a risk of irreparable impairment to clutch slave cylinder. Practise not press clutch pedal after removing clutch slave cylinder. |  |

| Vehicles with starting time/stop organization:

Continued for all vehicles: |  |

|  |

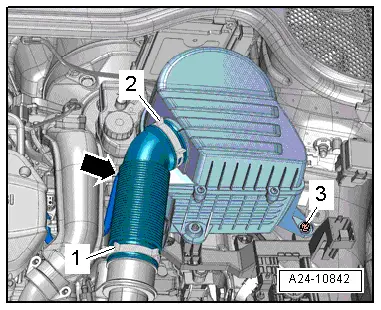

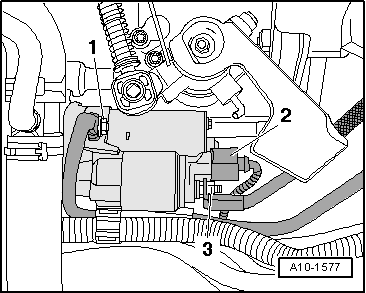

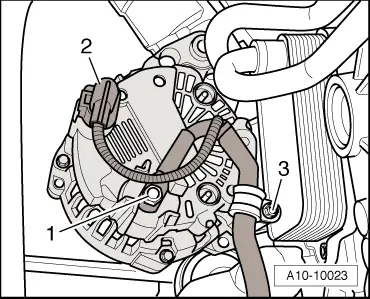

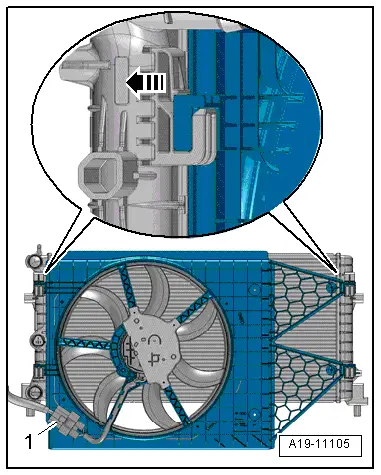

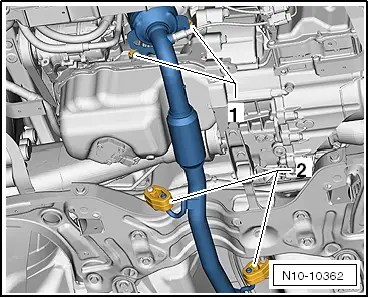

-Item ane- and -detail 3- can exist disregarded. |  |

|  |

|  |

|  |

|  |

|  |

|  |

|  |

|  |

|  |

|  |

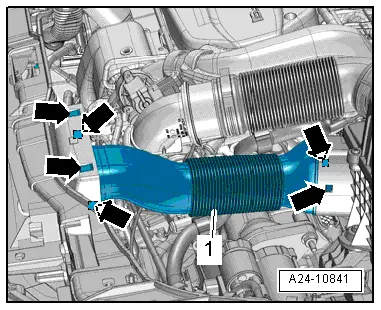

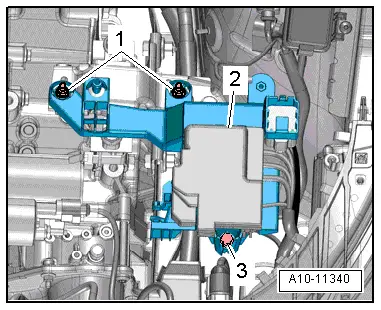

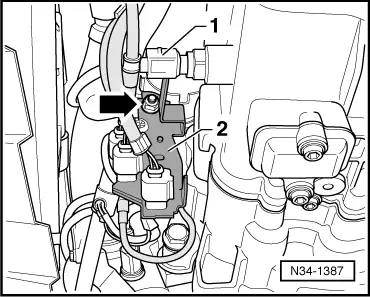

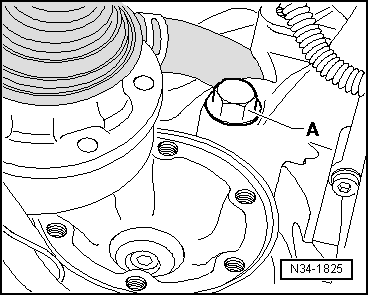

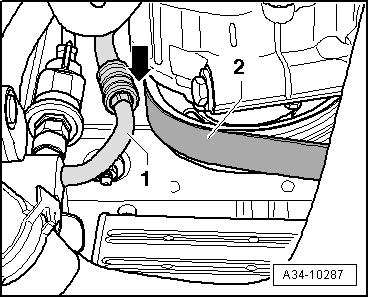

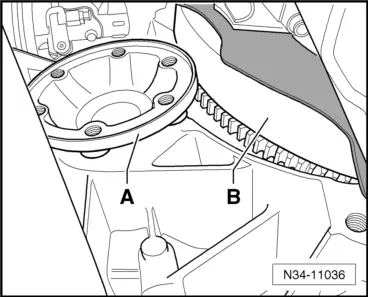

| Hazard of accident. The bolted connectedness -1- must not be slackened.

|  |

|  |

|  |

|  |

|  |

|  |

|  |

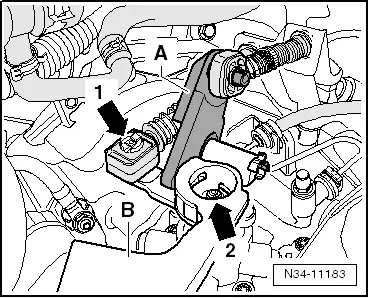

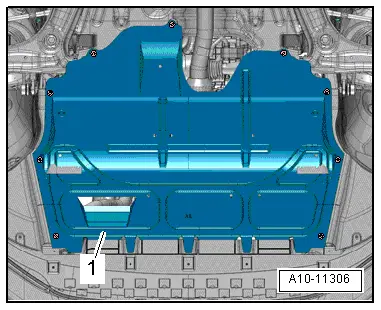

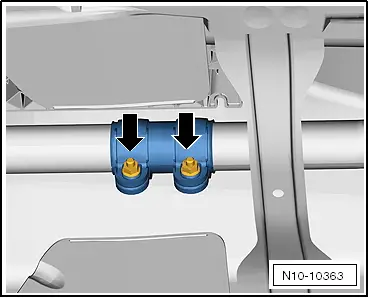

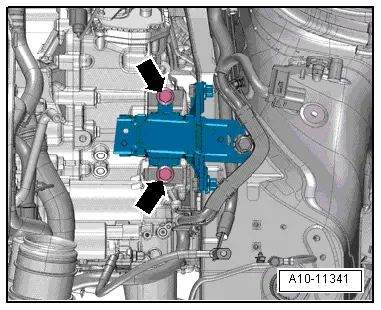

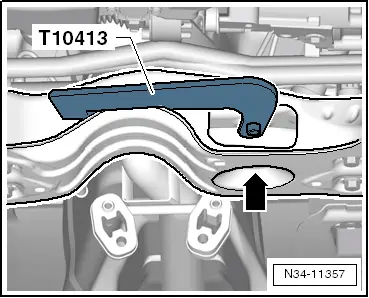

Place flat safety cake -pointer- between the 2 to protect sump.

|  |

|  |

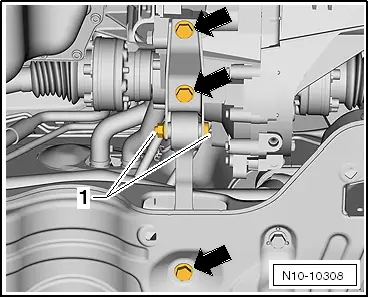

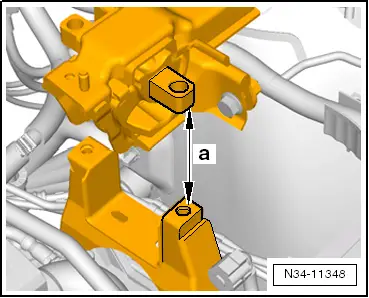

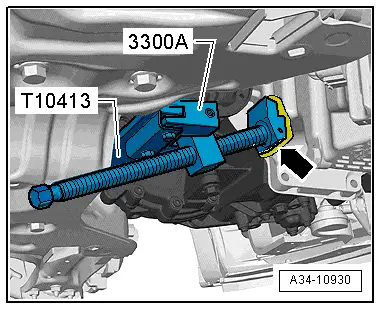

| To remove gearbox „02U", set up gearbox support -3282- with aligning plate -3282/31-.

|  |

|  |

|  |

|  |

< PREV PAGE Side by side Folio >

DOWNLOAD HERE

1963 Ford 4000 Manual Steering Gear Box Exploded View UPDATED

Posted by: ronaldusbal1959.blogspot.com

Note

Note Caution

Caution WARNING

WARNING

0 comments:

Post a Comment